From turbo-jet engines to Holos generators

In a global market dominated by low-cost natural gas, large and small reactor technologies cannot be competitive. For nuclear technologies to simultaneously increase safety, reduce costs and compete with non-nuclear electricity producing technologies, a radically innovative approach is necessary. Holos generators adopt a unique architecture that integrates proven commercial technologies to produce affordable pollutant-free electricity with safer melt-tolerant fuels. Holos functioning principles are similar to those represented by a “closed-loop” turbo-jet engine, wherein the conventional “combustors” are replaced by reinforced sealed fuel cartridges. Similar types of nuclear engines were successfully tested as part of U.S. government sponsored programs in the fifties and sixties .

Safe and reliable turbojet engine components combined with off-the-shelf products utilized by multiple industries (e.g. automotive, renewable, aviation and stationary power generation), are integrated to form Holos generators power conversion components. Through the unique Holos approach, the typical “open-loop” Brayton turbo-jet engine is modified into a “closed-loop” system wherein the turbojet combustion system is replaced by sealed nuclear fuel cartridges. In the Holos configuration, to further increase safety, air is replaced with a gas (e.g. Helium or Carbon Dioxide) whose energy content is increased as it flows through the fuel cartridge to expand through turbo-machinery and produce electricity. Similar systems were extensively tested through U.S. government sponsored programs. More than 50 years later, Holos takes advantage of modern and safer fuels, closes the loop to further seal all of the components forming the generator and couples the heat source directly to the electric-power producing system. Overall, off-the-shelf turbo-machinery components from aviation industry, direct-drive generators from renewable (e.g. wind-powered systems) and waste heat recovery systems, hybrid automotive and high-power electric motors, inverters and electronic controllers are integrated and sealed to form Holos subcritical power modules. Holos architecture enables substantial design simplifications while enhancing safety, reducing construction and licensing time and costs. This results in a competitive and synergetic alternative to both fossil and renewable technologies.

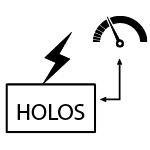

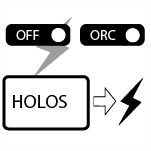

Holos Subcritical Power Module Functioning Principles

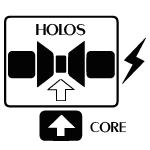

Automatic Module Positioning System (AMPS)

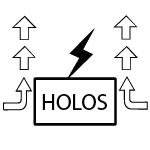

Holos core is formed by coupling a minimum number of independent subcritical integral power modules. The name Holos comes from the Greek for “whole” as the core is formed by multiple subcritical power modules sealed in independent steel pressure vessels. The resulting coupled core becomes critical (able to sustain nuclear chain reactions) and produces electric power only when a minimum number of Holos subcritical power modules are brought together, thus forming the whole core. Neutrons couple each fuel cartridges through controlled neutron leakage. The subcritical power modules are actively positioned by the Automatic Module Positioning System (AMPS) equipped with fast actuators with features similar to those represented by the redundant flight-control systems employed by the aviation industry. For example, landing gears, flaps, and flight-control surfaces are actuated by highly reliable systems with decades of operational experience. Three-phase, high-resolution load following electric power is produced by regulating the AMPS to increase/decrease the fuel cartridges’ thermal rating with near real-time power conversion (e.g. rapid power increase/decrease characteristics typical of aviation turbojet engines). In case of AMPS malfunctioning or failure, the subcritical power modules reposition themselves automatically or gravity-assisted with multiple and diversified passive features ensuring safe shutdown under all normal, off normal and threat basis scenarios.

Key Features

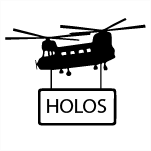

Deployable Everywhere

Different configurations of the design provide scalable power ratings from 3 MWe to 81 MWe with near real-time load following electricity. For electric power demand up to 13 MWe, a single transport container comprises the whole mobile operational generator. The components, can also be transported individually for maintenance, refurbishing or replacement. Generators can be re-licensed for a total life-span of 60 years.